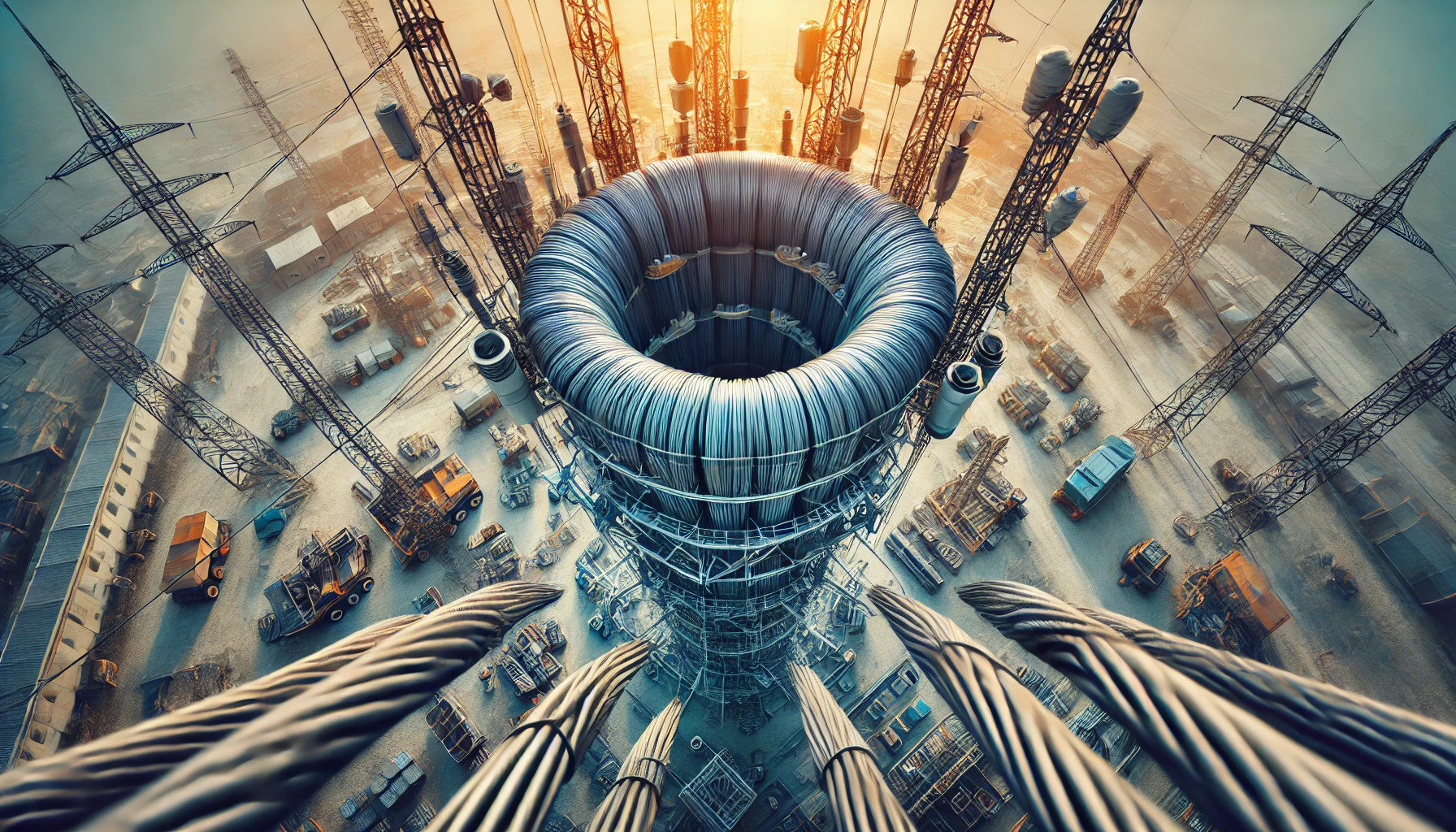

Measuring neck tension in 6 mm broma cables is a critical task in various fields, including construction, telecommunications, and engineering. Proper tension ensures the cable’s durability, functionality, and safety. This guide offers a comprehensive overview, helping professionals and DIY enthusiasts alike achieve accurate and reliable results.

What Is Neck Tension in 6 mm Broma Cables?

Neck tension refers to the force exerted along the length of a cable, which determines its stability and load-bearing capacity. For 6 mm broma cables, proper tensioning is essential to prevent failures and ensure long-term performance. Factors such as material composition, environmental conditions, and application type influence the ideal neck tension.

Importance of Measuring Neck Tension

Accurate neck tension measurement is crucial for several reasons:

- Safety: Improperly tensioned cables can lead to accidents, structural damage, or system failures.

- Durability: Over-tensioning or under-tensioning reduces the cable’s lifespan.

- Functionality: Correct tension ensures the cable performs optimally in its intended application.

For industries relying on 6 mm broma cables, regular tension assessments are a must.

Tools and Techniques for Measuring Neck Tension

Traditional Tools

Traditional tools, such as mechanical tensiometers, provide a simple way to measure cable tension. These devices rely on calibrated springs and scales, offering a basic level of accuracy. However, they can be less reliable for precise applications.

Advanced Methods

Modern tools enhance accuracy and efficiency:

| Tool | Description | Advantages |

| Digital Tension Meters | Devices that provide digital readouts of tension levels. | High precision, easy to read. |

| Load Cells | Sensors that measure force applied to the cable. | Extremely accurate, suitable for heavy-duty tasks. |

| Ultrasonic Tension Meters | Non-invasive tools using sound waves to assess tension. | Advanced technology, no physical contact needed. |

Step-by-Step Guide to Measuring Neck Tension in 6 mm Broma Cables

Preparation

Before starting, ensure you have the appropriate tools for the job. Inspect the cable for visible damage, such as fraying or corrosion, which can affect measurements. Work in a controlled environment to minimize external influences like temperature or wind.

Measurement Process

- Attach the Device: Secure the measuring tool to the cable according to the manufacturer’s instructions.

- Take Readings: Apply the tool to measure tension. For digital tools, ensure the display is clear and stable.

- Record Results: Document the readings for future reference or adjustments.

Common Mistakes to Avoid

- Not calibrating tools before use.

- Ignoring external factors such as uneven loading.

- Using inappropriate tools for the cable size or material.

Analyzing Tension Results

Understanding the results is as important as taking the measurements. The ideal tension range for 6 mm broma cables varies depending on the application but should fall within safe operational limits. Deviations indicate potential issues such as overuse, wear, or incorrect installation.

Applications of Proper Neck Tension

Construction

In construction, proper tension prevents structural failures. For example, broma cables used in bridges or high-rise buildings must withstand heavy loads without compromising safety.

Telecommunications

In telecommunications, tension affects signal quality and transmission efficiency. Maintaining proper neck tension ensures consistent performance over long distances.

Industrial Use

Industrial applications demand cables that can endure extreme conditions. Proper tensioning minimizes the risk of operational downtime and equipment damage.

Maintenance Tips for 6 mm Broma Cables

- Conduct periodic inspections to identify signs of wear.

- Store cables in a dry environment to prevent corrosion.

- Use protective coatings to enhance durability in harsh conditions.

Future Innovations in Measuring Neck Tension

The future of neck tension measurement includes AI-powered devices and IoT-enabled systems that provide real-time monitoring and automated adjustments. These technologies promise greater accuracy and ease of use, revolutionizing the way tension is managed.

FAQs

- What is the recommended frequency for measuring neck tension? Ideally, tension should be measured every 3-6 months, depending on the application.

- Can I use a single tool for all cable types? No, tools must be compatible with the cable’s material, diameter, and application.

- What happens if the tension is too high? Over-tensioning can cause the cable to snap or lose its structural integrity over time.

- Are digital tools better than mechanical ones? Digital tools offer greater precision and ease of use, making them preferable for most applications.

- How do environmental factors affect tension? Temperature changes can cause cables to expand or contract, impacting tension levels. Humidity can lead to corrosion, weakening the cable.

Conclusion

Measuring neck tension in 6 mm broma cables is essential for ensuring safety, functionality, and longevity. By using the right tools and techniques, and understanding the importance of regular checks, you can avoid potential issues and maintain optimal performance. Whether you’re in construction, telecommunications, or industrial sectors, proper tension management is a cornerstone of operational success.

Recommended Articles:

- The Life and Legacy of Zella G. Wright in Marysville CA

- The Ultimate Guide to Unlocking atelier iris get mofuma to unlock leheruun cream

- Michael G. Apicella frederick md: Your Comprehensive Guide to a Leading Physician in Frederick, MD

- Rowland St & S Barranca Ave Red Light Camera: A Detailed Guide

- Mathew Pomyanovskyy: A Comprehensive Guide to the Business Visionary

Leave a Reply