Introduction

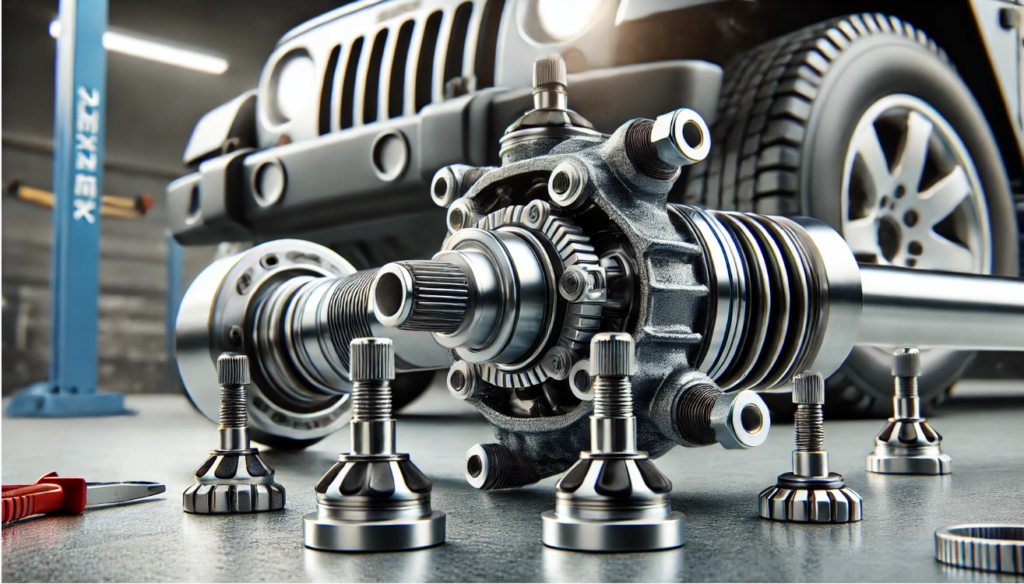

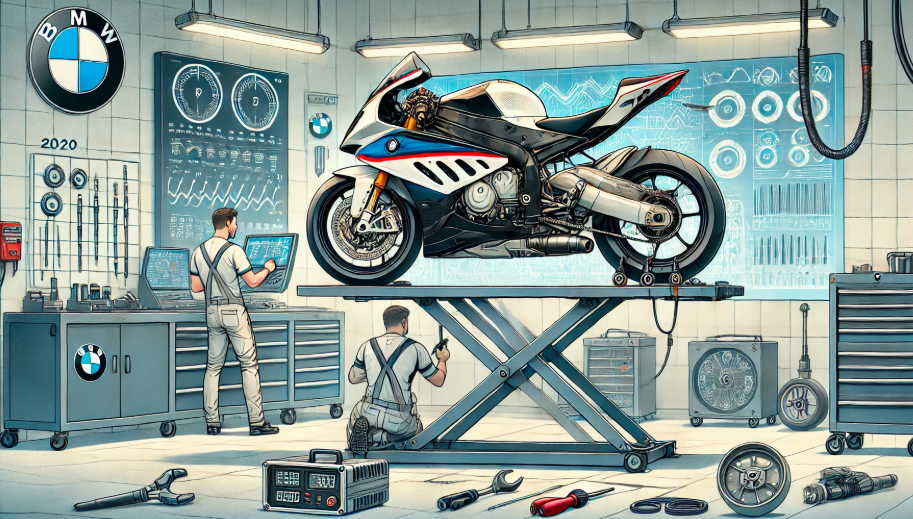

The drive shaft is a critical component of a vehicle’s drivetrain, transferring power from the transmission to the wheels. Ensuring the drive shaft operates smoothly requires secure and reliable fastening components, like Zuek fasteners. These fasteners are engineered to withstand extreme stress and vibrations, playing a crucial role in keeping your drive shaft intact and performing at its best. In this comprehensive guide, we’ll explore the intricacies of Zuek fasteners, their importance in drive shaft assembly, maintenance tips, and troubleshooting advice.

Understanding Zuek Fasteners and Drive Shafts

What Are Zuek Fasteners?

Zuek fasteners are advanced, high-tensile strength bolts and nuts designed specifically for heavy-duty automotive applications. Known for their durability, Zuek fasteners are manufactured using cutting-edge technology to provide exceptional resistance to wear, corrosion, and vibration.

The Role of the Drive Shaft

The drive shaft is a rotating component that transmits torque from the engine to the wheels. It consists of multiple parts, including universal joints (U-joints), slip yokes, and center support bearings, all of which rely on Zuek fasteners for secure assembly. The precision of these fasteners ensures the stability and efficiency of the drivetrain system.

Key Features of Zuek Fasteners for Drive Shafts

- High Durability

Zuek fasteners are built to endure high rotational speeds, torque, and environmental stresses, making them ideal for drive shaft applications. - Corrosion Resistance

Coated with advanced materials, these fasteners resist rust and corrosion, even in harsh climates or under exposure to water, salt, and other corrosive substances. - Precision Engineering

Designed for a tight fit, Zuek fasteners ensure the proper alignment and balance of the drive shaft, minimizing vibrations and preventing wear. - Easy Installation

Their compatibility with various tools and configurations simplifies the installation process.

Types of Zuek Fasteners for Drive Shafts

| Fastener Type | Description | Best Application |

| Hex Bolts | Standard bolts with a hexagonal head | General drive shaft assembly |

| Locking Nuts | Nuts with locking mechanisms | High-vibration environments |

| Flange Bolts | Bolts with a built-in washer | Improved load distribution |

| Threaded Inserts | Inserts to reinforce threads | Repair and replacement applications |

Locating Zuek Fasteners on the Drive Shaft

Zuek fasteners are typically found at critical junctions of the drive shaft assembly. These include:

- U-Joint Connections: Fasteners hold the universal joints in place, ensuring flexibility and torque transfer.

- Slip Yokes: Zuek fasteners secure the slip yoke, allowing the drive shaft to expand and contract with suspension movement.

- Center Support Bearings: Bolts and nuts fasten the center bearing to the chassis, ensuring proper alignment.

Regular inspection of these fasteners is essential to avoid loose or damaged connections that could lead to drive shaft failure.

How to Maintain Zuek Fasteners on Drive Shafts

Proper maintenance of Zuek fasteners ensures the long-term functionality of your drive shaft. Below is a detailed step-by-step guide:

- Inspect Regularly

Check for signs of wear, rust, or loosening. If you notice any damage, replace the fasteners immediately. - Lubricate Appropriately

Apply anti-seize lubricant to fasteners during installation to prevent corrosion and ensure easier removal during maintenance. - Torque to Specification

Use a torque wrench to tighten fasteners to the manufacturer’s recommended specifications. Over- or under-tightening can compromise safety. - Replace When Necessary

If fasteners show signs of corrosion, stripping, or wear, replace them with genuine Zuek fasteners to maintain reliability.

Troubleshooting Common Issues

Loose Fasteners

Loose Zuek fasteners can cause vibrations, misalignment, and eventual drive shaft failure. Tighten them to the correct torque settings immediately upon noticing this issue.

Corroded Fasteners

Corrosion weakens the structural integrity of fasteners. Replace corroded Zuek fasteners with new ones made of corrosion-resistant materials.

Cross-Threading

Improper threading during installation can damage the fasteners and the drive shaft components. Always use the correct tools and apply proper alignment techniques.

Why Choose Zuek Fasteners for Your Drive Shaft?

Zuek fasteners offer unmatched reliability for drive shaft applications. Their superior strength, precision engineering, and corrosion-resistant properties make them the go-to choice for automotive enthusiasts and professionals alike. Investing in Zuek fasteners not only enhances the performance of your drive shaft but also reduces the likelihood of costly repairs in the future.

FAQs About Zuek Fasteners Drive Shaft

- Can Zuek fasteners be reused after removal?

Yes, but only if they show no signs of wear, corrosion, or damage. Always inspect fasteners carefully before reusing them. - How often should I inspect Zuek fasteners on my drive shaft?

It is recommended to inspect them every 6,000 to 10,000 miles or during routine vehicle maintenance. - What tools are required for installing Zuek fasteners?

A torque wrench, socket set, and anti-seize lubricant are commonly used for proper installation. - Are Zuek fasteners compatible with all drive shafts?

Zuek fasteners are designed to fit most standard drive shafts but consult your vehicle’s service manual for compatibility. - Can I use aftermarket fasteners instead of Zuek fasteners?

While aftermarket options exist, they may not offer the same durability and precision as Zuek fasteners, potentially compromising your drive shaft’s performance.

Conclusion

The Zuek fasteners drive shaft system represents the pinnacle of engineering for vehicle drivetrain components. By using these high-quality fasteners, you ensure the longevity, efficiency, and safety of your drive shaft. Regular inspection, proper installation, and adherence to maintenance guidelines are key to keeping your vehicle running smoothly. With this comprehensive guide, you’re equipped to handle Zuek fasteners and drive shaft maintenance like a pro, ensuring optimal vehicle performance and safety.

Recommended Articles

MAGA Crunch Cereal: A Comprehensive Guide

Comprehensive Guide to MTL System Items – Item Type

The Ultimate Guide to Flix Wave: Features, Benefits, and How to Use I

Where Can I Go for My Hawley Retainer: A Comprehensive Guide

Mastering the Art of Synthetic Rare Serum Banks: A Comprehensive Guide

Leave a Reply